tennant t350 parts manual

Tennant T350 Parts Manual: A Comprehensive Guide

This guide details ordering genuine Tennant parts or equivalents, referencing diagrams for accurate identification․ Online ordering is available, with manuals ranging from 106 to 136 pages, aiding maintenance and repair efforts․

The Tennant T350 represents a robust and reliable solution for commercial and industrial floor cleaning needs․ This walk-behind scrubber is engineered for efficiency, offering a balance of performance and maneuverability, making it a popular choice across diverse facilities․ Understanding its components and how to maintain them is crucial for maximizing its lifespan and cleaning effectiveness․

This introduction sets the stage for a comprehensive exploration of the Tennant T350’s parts and maintenance․ Proper identification and replacement of components are essential, and this guide emphasizes the importance of utilizing Tennant Company supplied parts or verified equivalents․ A variety of floor cleaning machines are available, including robotic scrubbers, but this manual focuses specifically on the T350 model․

Whether you’re a facility manager, maintenance technician, or owner-operator, this resource will provide valuable insights into the T350’s inner workings․ It will help ensure optimal performance and minimize downtime, ultimately contributing to a cleaner and safer environment․ Regular maintenance, guided by this manual, is key to preventing costly repairs and extending the machine’s operational life․

Understanding the Importance of a Parts Manual

A comprehensive parts manual is indispensable for the effective maintenance and repair of any complex machine, and the Tennant T350 is no exception․ It serves as a detailed roadmap to the machine’s internal components, facilitating accurate identification and ordering of replacement parts․ Utilizing the correct parts – either directly from the Tennant Company or verified equivalents – is paramount to ensuring optimal performance and preventing further damage․

Without a parts manual, troubleshooting becomes significantly more challenging, potentially leading to misdiagnosis and incorrect repairs․ This can result in increased downtime, higher maintenance costs, and compromised cleaning quality․ Manuals, often exceeding 100 pages, provide exploded diagrams and part numbers, streamlining the ordering process․

Furthermore, a parts manual empowers technicians and facility personnel to perform preventative maintenance effectively․ Understanding the location and function of each component allows for proactive inspections and timely replacements, extending the T350’s operational life and maximizing its return on investment․ Adhering to the manual’s guidance is crucial for maintaining warranty validity and ensuring safe operation․

Locating the Correct Parts

Accurate part identification relies on detailed diagrams, ensuring compatibility․ Ordering is streamlined through Tennant’s online platform, prioritizing genuine or equivalent components for optimal machine performance․

Using the Tennant Parts Diagram

The Tennant T350 parts diagram is crucial for successful component identification and ordering․ These diagrams, often found within the comprehensive manuals (ranging from 106 to 136 pages, and even up to 124 pages depending on the specific section), provide a visual representation of the machine’s assembly․ Each part is typically labeled with a specific reference number, directly corresponding to its part number in the accompanying parts list․

Effective use of the diagram involves carefully comparing the visual representation of the required part with the actual component needing replacement․ Pay close attention to details like shape, size, and any unique features․ The diagram will also illustrate how the part interacts with surrounding components, aiding in understanding its function and proper installation․

Tennant diagrams are structured to show exploded views, separating components for clarity․ This allows users to easily pinpoint the exact part needed without confusion․ Remember to always cross-reference the diagram’s part number with the official Tennant parts list to ensure accuracy before placing an order․ Utilizing the diagram correctly minimizes errors and ensures the correct replacement part is obtained, maximizing machine uptime and performance․

Tennant Company Supplied vs․ Equivalent Parts

When maintaining a Tennant T350, the choice between Tennant-supplied parts and equivalent alternatives is significant․ Tennant Company strongly recommends using genuine Tennant parts to guarantee optimal performance, longevity, and compatibility with your machine․ These parts are engineered specifically for the T350, ensuring a precise fit and reliable operation․

However, equivalent parts are permissible, but careful consideration is vital․ “Equivalent” signifies a part manufactured by a different company that meets or exceeds Tennant’s specifications for the original component․ It’s crucial to verify that any equivalent part is truly compatible and won’t void any warranties or compromise the machine’s functionality․

Using non-equivalent or substandard parts can lead to reduced cleaning efficiency, increased wear and tear, and potential damage to the T350․ Always prioritize quality and ensure the equivalent part meets the required standards․ Referencing the parts manual and consulting with a Tennant service professional can help determine suitable equivalent options, balancing cost-effectiveness with machine integrity․ Only use TENNANT Company supplied or equivalent parts, as repeatedly emphasized in available documentation․

Online Parts Ordering Process

Tennant Company facilitates a streamlined online parts ordering process for the T350, ensuring convenient access to necessary components․ Typically, this involves navigating to the official Tennant website and accessing the parts section, often requiring account creation or login for authorized customers․

The process usually begins with identifying the specific part needed, utilizing the Tennant parts diagram (detailed elsewhere in this manual) to pinpoint the correct part number․ Once identified, the part number is entered into the online search function․ The system will display available stock, pricing, and estimated shipping times․

Adding the desired parts to your cart and proceeding to checkout initiates the order․ Secure payment options are generally available, and order confirmation is typically sent via email․ Parts and supplies may be ordered online, as consistently stated in available resources․ Reviewing order details and shipping addresses before final submission is crucial․ Tennant’s online platform aims for efficient parts procurement, minimizing downtime and supporting consistent machine operation․

Key Components and Replacement Parts

Essential replacements include brush system parts, squeegee assemblies and blades, and solution delivery components․ Drive system elements, like motors and tires, also require periodic attention and upkeep․

Brush System Components

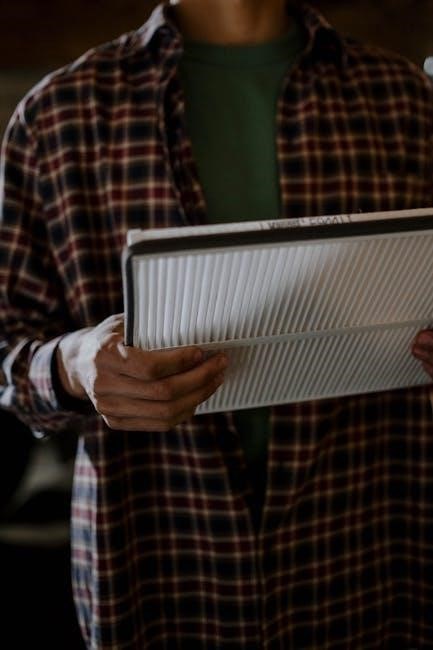

The brush system is critical for effective floor scrubbing on the Tennant T350․ Replacement components include brush heads, brush motors, and brush skirts․ Different brush materials are available – nylon, polypropylene, and abrasive brushes – suited for varying floor types and cleaning needs․ Regular inspection of brush wear is essential; worn brushes reduce cleaning efficiency and can potentially damage the floor surface․

Tennant recommends using genuine Tennant brushes or approved equivalents to maintain optimal performance and warranty compliance․ Brush motors should be checked for proper operation, ensuring adequate power and speed․ Brush skirts, which contain the cleaning solution and prevent splashing, require periodic replacement as they become worn or damaged․ Proper brush installation and tension adjustment are also vital for maximizing cleaning effectiveness and extending component lifespan․ Refer to the parts manual diagrams for correct component identification and ordering․

Consider the specific application when selecting replacement brushes․ For heavily soiled areas, abrasive brushes may be necessary, while softer brushes are ideal for delicate flooring․ Maintaining a well-maintained brush system significantly contributes to the overall cleaning performance and longevity of the Tennant T350․

Squeegee Assembly and Blades

The squeegee assembly on the Tennant T350 is responsible for vacuuming up the cleaning solution, leaving floors dry and safe․ Key components include the squeegee blades, squeegee frame, and vacuum motor․ Squeegee blades are wear items and require frequent inspection and replacement to ensure effective water removal․ Different blade materials, such as polyurethane and rubber, are available, each offering varying levels of durability and flexibility․

Worn or damaged squeegee blades result in streaking and water left behind, compromising cleaning results and potentially creating slip hazards․ The squeegee frame should be checked for cracks or damage, and the vacuum motor inspected for proper suction․ Proper blade alignment and downforce adjustment are crucial for optimal performance․ Tennant recommends using genuine Tennant squeegee blades or approved equivalents․

Refer to the parts manual diagrams for correct blade identification and installation procedures․ Regular maintenance of the squeegee assembly, including blade replacement and vacuum system checks, is essential for maintaining a clean and safe floor surface with the Tennant T350․

Solution Delivery System Parts

The Tennant T350’s solution delivery system ensures consistent and effective cleaning․ Critical components include the solution tank, solution pump, and spray nozzles․ The solution tank holds the cleaning solution, while the pump delivers it to the spray nozzles at the appropriate pressure․ Nozzles distribute the solution evenly across the floor surface for optimal cleaning performance․

Regular inspection of the solution tank for cracks or leaks is vital, alongside checking the pump for proper operation and consistent flow rate․ Clogged or damaged spray nozzles can lead to uneven solution distribution and reduced cleaning effectiveness․ Tennant recommends using genuine Tennant cleaning solutions and replacement parts to maintain system integrity․

The parts manual provides detailed diagrams illustrating the location and identification of each component․ Filter replacement within the solution system is also crucial to prevent debris from damaging the pump and nozzles․ Maintaining this system guarantees optimal cleaning results and prolongs the lifespan of the Tennant T350․

Drive System Components (Motors, Tires)

The Tennant T350’s drive system is fundamental to its operational efficiency, comprising drive motors and tires․ These motors provide the power for movement, while the tires ensure traction and maneuverability․ Regular maintenance of these components is crucial for preventing downtime and ensuring consistent performance․

The parts manual details the specifications of the drive motors, including voltage and horsepower ratings, aiding in accurate replacement․ Tire wear should be monitored regularly, and tires replaced when tread depth diminishes, impacting traction․ Inspecting the motors for signs of overheating or unusual noises is also essential․

Tennant recommends utilizing genuine Tennant replacement parts for both motors and tires to guarantee compatibility and maintain the machine’s original performance standards․ Proper alignment of the drive system is vital to minimize wear and tear․ Referencing the parts diagram assists in identifying the correct components for repair or replacement, maximizing the T350’s operational lifespan․

Maintenance and Troubleshooting

Regular maintenance prevents issues, while troubleshooting guides address common problems․ Filter replacements are key, and the parts manual aids in identifying components for swift, effective repairs and upkeep․

Common Tennant T350 Issues

Identifying frequent Tennant T350 problems is crucial for efficient maintenance․ A common issue involves the solution delivery system, potentially stemming from clogged filters or a malfunctioning pump – referencing the parts manual is vital for correct component identification and replacement․ Drive system concerns, like tire wear or motor inefficiencies, also arise, necessitating inspection and potentially new parts․

Brush system failures, including worn bristles or motor issues, impact cleaning performance․ Squeegee problems, such as blade damage or improper assembly, lead to streaking․ Utilizing the parts diagram within the manual ensures accurate ordering of replacements․ Regularly checking these components, guided by the manual’s illustrations, minimizes downtime․

Furthermore, electrical issues can occur, requiring careful diagnosis and potentially specialized parts․ Always prioritize safety and consult the manual for proper procedures․ Proactive maintenance, informed by the parts manual, significantly reduces the frequency of these common Tennant T350 issues․

Preventative Maintenance Schedules

Establishing a robust preventative maintenance schedule for your Tennant T350, guided by the parts manual, is paramount for longevity․ Daily checks should include inspecting the brush system – bristles, motors – and the squeegee assembly for wear, referencing the diagram for component locations․ Weekly tasks encompass a thorough solution delivery system review, focusing on filter cleanliness and pump functionality, utilizing parts listed in the manual․

Monthly maintenance should involve a detailed drive system inspection, checking tire pressure and motor operation․ Quarterly, examine electrical connections and conduct a comprehensive cleaning of all components․ The parts manual aids in identifying necessary replacements․ Annually, a professional service is recommended, utilizing genuine Tennant parts or approved equivalents․

Adhering to this schedule, and referencing the parts manual for accurate component identification, minimizes downtime and extends the T350’s operational life․ Consistent maintenance, informed by the manual, ensures optimal performance and reduces costly repairs․

Filter Replacement Guidelines

Regular filter replacement is crucial for maintaining the Tennant T350’s cleaning performance and protecting its internal components․ The parts manual details specific filter types and their corresponding part numbers, ensuring correct replacements․ Solution filters should be checked monthly and replaced quarterly, or more frequently with heavily soiled water, preventing clogging and maintaining suction․

Dust filters, vital for protecting the vacuum system, require monthly inspection and replacement every six months, or as needed based on operating environment․ Air filters, safeguarding the motors, should be checked quarterly and replaced annually․ Always consult the parts manual for the correct filter specifications․

Proper filter replacement, guided by the manual, ensures optimal cleaning efficiency and prevents damage to pumps and motors․ Using genuine Tennant filters or approved equivalents guarantees compatibility and performance․ Documenting filter replacement dates aids in maintaining a consistent maintenance schedule, extending the T350’s lifespan․

Legal Aspects of Tennant Usage & Tenancy

Tenancy agreements should clarify utility responsibilities, detailing who manages accounts․ Joint tenancy transfers full property ownership upon a tenant’s death, unlike tenancy-in-common․

Tenancy Agreements and Lease Considerations

Before finalizing a tenancy, tenants may encounter an “agreement for lease”, a provisional document outlining future terms․ Thoroughly review all clauses within the formal tenancy agreement or lease before signing, paying close attention to stipulations regarding maintenance responsibilities and potential alterations to the property․

Understanding the document’s handling post-signature is crucial․ Both landlord and tenant should retain copies for their records, referencing them for clarification on rights and obligations․ A well-defined lease minimizes disputes and ensures a smooth tenancy․ Consider legal counsel for complex agreements or if uncertainties arise․

Furthermore, the lease should clearly address rent payment schedules, late fee policies, and procedures for lease renewal or termination․ Documenting any agreed-upon changes or amendments to the original lease is vital, ensuring both parties acknowledge and consent to the modifications in writing․ This proactive approach fosters a transparent and legally sound landlord-tenant relationship․

Joint Tenancy vs․ Tenancy-in-Common

Joint tenancy features a right of survivorship; upon one tenant’s death, their ownership share automatically transfers to the surviving joint tenant(s), consolidating full property ownership․ This differs significantly from tenancy-in-common, where each tenant holds a distinct, individual share․

In a tenancy-in-common arrangement, a deceased tenant’s interest doesn’t automatically pass to co-tenants․ Instead, it becomes part of their estate and is distributed according to their will or inheritance laws․ This allows for greater flexibility in estate planning, as tenants can bequeath their share to anyone they choose․

The choice between these two tenancy types has substantial legal and financial implications․ Joint tenancy simplifies property transfer upon death, while tenancy-in-common offers more control over asset distribution․ Understanding these distinctions is crucial for tenants and landlords alike, particularly when multiple parties are involved in property ownership and estate planning considerations․

Utility Account Responsibilities (Tenant vs․ Landlord)

Determining utility responsibility is vital in tenancy agreements․ Landlords and tenants must clarify who manages accounts for services like water, drainage, and electricity․ Often, tenants directly open and maintain accounts with utility companies for their unit, ensuring consistent service and direct billing․

However, some leases stipulate the landlord retains responsibility for certain utilities, potentially including them in the monthly rent․ This requires clear documentation outlining which utilities are covered and any limitations on usage․ A provisional tenancy agreement or agreement for lease may initially address these responsibilities before a formal lease is signed․

Properly defining these responsibilities prevents disputes and ensures smooth operation․ Tenants should understand their obligations for timely payments and reporting any service issues․ Landlords must ensure accurate billing and maintain the property’s utility infrastructure․ Clear communication and a well-defined lease agreement are essential for avoiding misunderstandings regarding utility account management․

Leave a Reply

You must be logged in to post a comment.